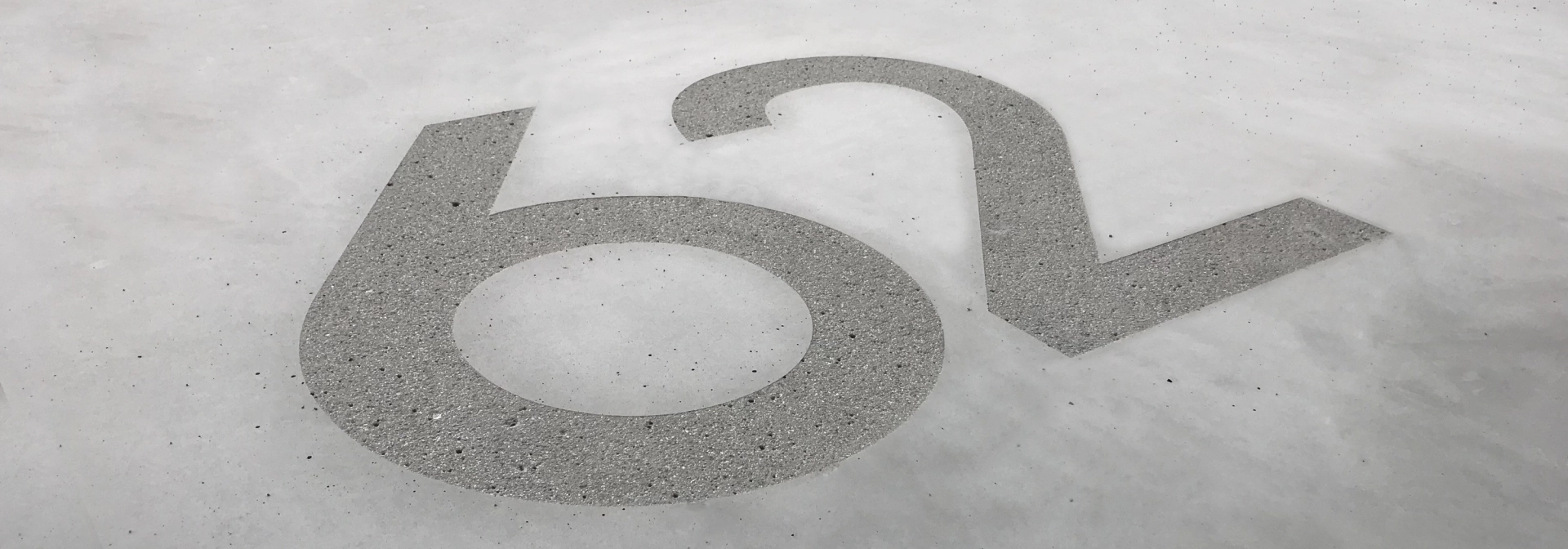

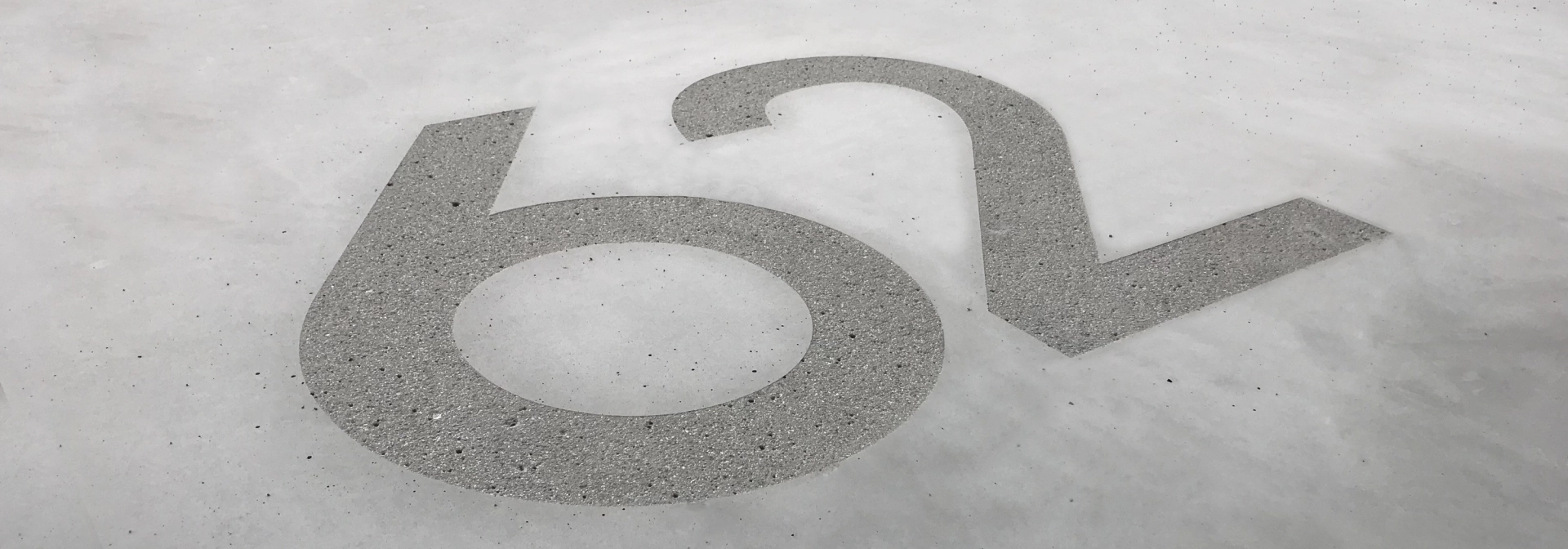

Almost all of our handmade elements in the visia surface can be blasted with individual motifs during production. The prerequisite is the provision of the data as a two-color vector file. We then adapt the motif precisely to the component and initiate the approval process. After successful coordination, the component goes into our in-house blasting cabin and is further processed by hand with precision. This type of customization is perfect for company logos or house numbers on steles or wall panels. There are virtually no limits to your imagination.

Inlays are a particularly stylish and elegant way of showcasing handmade components. Our specialists delicately work them into the mold by hand and cast them directly into the component during the production process. After demolding, protrusions and burrs are removed and, depending on the material, cleaned or polished.