The ever-increasing sealing of traffic areas and buildings is disrupting the natural water balance. As a result, sewer systems are very quickly overloaded during rain events and the risk of flooding has increased. In order to reduce the negative consequences of constantly increasing sealing, the use of rainwater, decentralized drainage systems and the unsealing of traffic areas are becoming increasingly important. In addition to increased ecological awareness, which is now also reflected in building regulations,

However, there are also a variety of economic reasons for making traffic areas permeable. For example, rising costs for the extraction and provision of clean drinking water are a burden on the budgets of cities and municipalities. This can only be counteracted by protecting water bodies from contamination. Private households will be relieved if they no longer have to pay charges for rainwater that is discharged into the public sewer system from sealed surfaces on their property as a result of the split wastewater charge.

The range of available options, such as rainwater harvesting and infiltration instead of discharge, as well as the positive experiences with them, has increased in recent decades. In this context, traffic areas that can be paved with infiltration-capable paving systems are becoming increasingly important, as they have developed into a key component of modern rainwater management.

Periods of drought caused by climate change have already led to groundwater levels falling and streams and rivers drying up in many areas. Precipitation can no longer seep away on parched soils and the increasing sealing of surfaces is further destroying the natural water balance and groundwater recharge. As a result, the increasingly frequent extreme weather conditions always cause flooding and billions in damage. It is becoming increasingly important to handle rainwater in an environmentally friendly way, following the example of the natural water balance. In settlement areas in particular, this can counteract a further drop in the groundwater level. Reducing the surface runoff of rainwater also relieves the existing sewer systems and sewage treatment plants and can mitigate flooding.

Rainwater is a precious resource for all living creatures and therefore requires special protection. We can no longer afford to allow rainwater that is not currently needed to run off unused. In addition to infiltration, sustainable rainwater management also includes measures that provide storage for times of drought and help to improve the microclimate in residential areas. As part of the federal government's national water strategy, a number of corresponding measures are already recommended, some of which are already part of municipal building law. The split wastewater charge, which separates the costs of wastewater and rainwater, provides a particularly positive impetus.

As a pioneer of ecological paving construction methods, we have been dealing with their function and effect as well as their application limits for over 40 years. We offer suitable solutions for all requirements and for every design requirement. Starting with systems that can be planted with greenery, through paving blocks and drainage joints, to systems that filter and evaporate rainwater. All systems combine ecological, water management and traffic requirements with design demands.

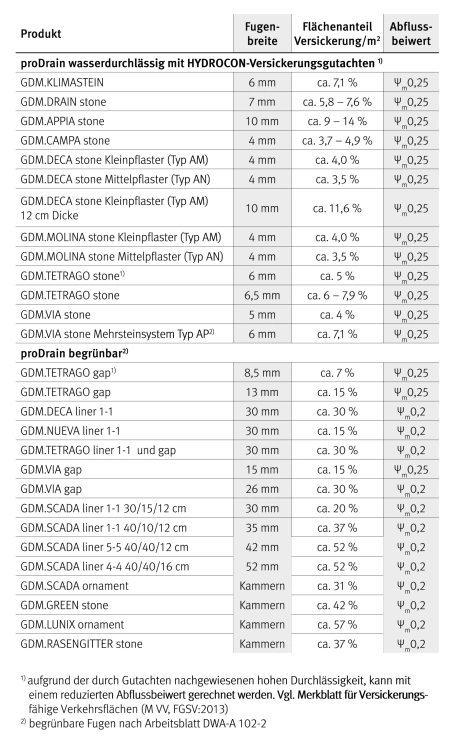

The runoff coefficients of different surfaces are used to classify the water flow in different situations from a water management perspective. Together with the so-called design rainfall rate, the runoff coefficients* can be used to plan drainage facilities and dimension appropriately sized infiltration systems.

Infiltration of surface runoff is always preferable to connection to the sewer system. In green spaces and soakaways, the water is cleaned as it passes through the living topsoil, can be absorbed by roots or is used for groundwater recharge.

Surfaces must be paved so that they can be driven on. In order to reduce the disturbance of the natural water balance to the minimum necessary, surfaces should not be sealed and a water-permeable construction method should be preferred instead. Sufficient permeability of the subsoil and all layers of the superstructure is always a prerequisite for permanently functioning ecological paving. These must be dimensioned according to the planned traffic load and compacted until they are stable. As stability is generally in conflict with water permeability, the construction material mixtures or substrates used to produce the base layers, bedding and joint filling must meet special requirements. The fine grain content should be limited to a maximum of 3 percent by mass and the impact crushing resistance should be adapted to the planned traffic load. As is usual with paving construction methods, the filter stability between the building material mixtures of successive layers must be maintained.

Runoff coefficients describe the percentage of precipitation that reaches the runoff. The initial value is the so-called design rainfall rate. The design rainfall rate is a specific value that is used for the planning and dimensioning of drainage systems. It corresponds to a 10-minute rainfall event with a statistical frequency of 5 years with a rainfall yield of 270 l / (sec x ha). In order to ensure that a property is not flooded uncontrollably during a heavy rainfall event, proof of flooding must be provided. In most cases, a rainfall event with a 30-year frequency is assumed and compared with the design rainfall. This makes it possible to determine how much water accumulates on a property and must be retained without causing damage so that it does not flow onto public roads or neighboring properties. Classic retention areas are, for example, grassed swales. However, tests have confirmed that paved areas are also suitable for retaining rainwater. With a maximum accumulation height of approx. 10 cm, it will generally seep into the superstructure after a short time. In the case of grassed swales, the rainwater is cleaned as it passes through the revitalized topsoil zone. Extensive infiltration on a paved surface, which has been produced in accordance with the specifications of a general construction permit, achieves a filtering capacity that corresponds to a living soil zone. If there are not enough green areas available for rainwater retention, the controlled flooding of a paved area, or even just a part of it, can be the measure that helps to fulfill the flooding certificate for the planned construction project.

They integrate a paved surface into the context of the surrounding green areas and do not primarily fulfill the purpose of infiltrating precipitation. They delay the surface run-off of rainwater, are generally resistant to heavy rainfall or flooding and can cool the surrounding area as moisture absorbed by the roots evaporates. Sand-rich crushed sand and grit mixtures, which may contain other additives to improve the vegetation properties, are suitable as bedding and jointing materials.

In the event of prolonged drought, it may be necessary to water the surface in order to maintain the vegetation. During maintenance, care must be taken to ensure that weeds and sprouting woody plants are removed as early and carefully as possible so that their roots do not spread into the bedding. Winter maintenance must not have any damaging effects on plants, which is why road salt and snow blades must not be used to remove snow. If there are requirements for barrier-free use of the surface, green paving systems alone are unsuitable and must be combined with paving stones or slabs with narrow joints in movement areas so that low-vibration use, e.g. with rollators, is possible.

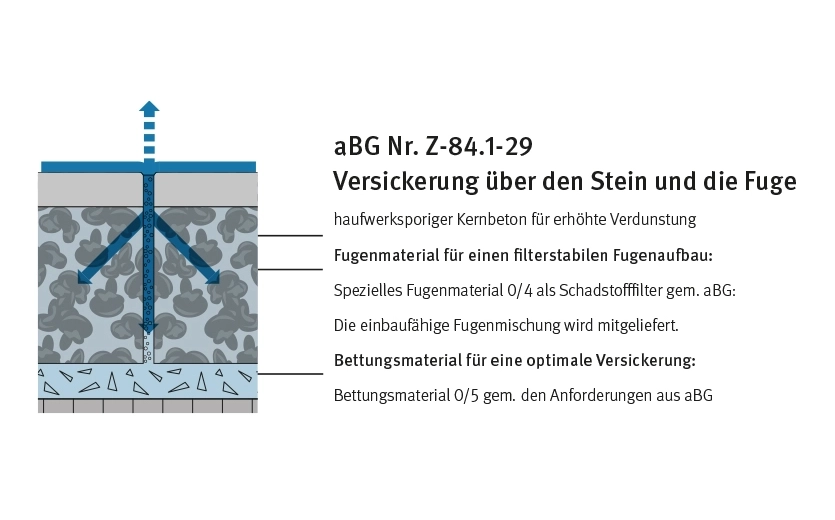

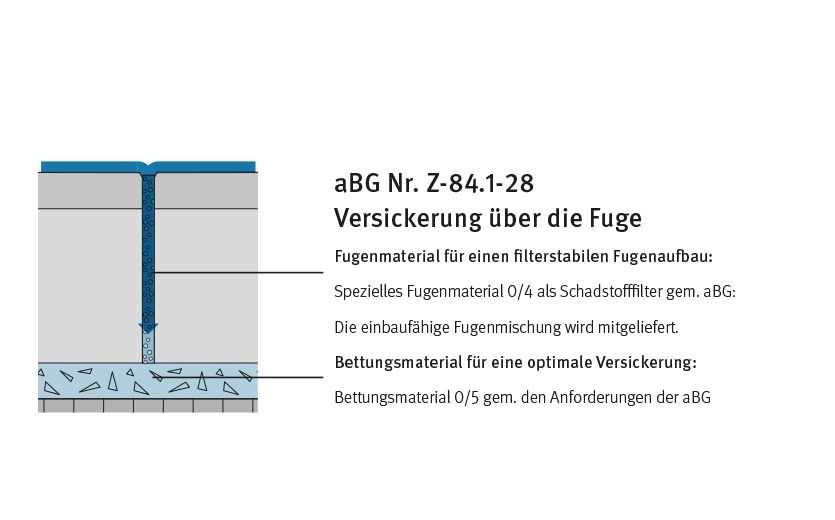

If the planning objective is to infiltrate the rainwater that accumulates on the traffic area, there are two proven systems for this: Paving stones with porous aggregates and drainage joint stones.

Paving blocks with spores absorb rainwater over their entire surface and infiltrate it into the superstructure. The joint surface plays a subordinate role in infiltration, which is why the joint work is generally based on the applicable regulations in accordance with the respective block thicknesses. The narrow joints allow for low-vibration and barrier-free use of the traffic area.

The core and facing layer must be made of aggregates with grading curves without fineness. Fine gradation makes it possible to form the facing layer as a filter layer. This filters out pollutants from the rainwater before it seeps into the superstructure. Above an average traffic load of 300 vehicles per day, rainwater runoff must not be discharged untreated into a body of water or allowed to seep away. The entire construction method has been tested by the DIBt and is regulated by a general construction type approval (aBG). This gives the surface covering the additional function of a treatment plant for rainwater (proWater).

Fine particles and pollutants are retained in the filter attachment and cannot permanently impair water permeability. The pavement surface must be cleaned regularly every 10 to 15 years using a rinsing and suction process. This removes dirt and pollutants from the filter attachment. The water permeability is reduced to a value that corresponds to approx. 90 % of the infiltration capacity in the freshly laid state.

It is therefore permissible to assume an average runoff coefficient of 0.0. A proportion of pore water always remains in the stone structure of the core and facing concrete. The moisture can evaporate after rain and thus cool the environment. Due to the open porosity, it is not possible to finish the surface of the stone, e.g. by grinding or blasting, and the color spectrum is generally limited to grey or anthracite. A stone structure with a large number of voids means a lower compressive strength than with dense concrete paving stones of the same format. For this reason, pavers with porous structure are recommended for areas with low traffic loads. Hard stone chippings with a grain size of 2-5 mm have proven to be a suitable bedding material, the joints are usually filled with chippings 1-3 mm. This ensures rapid drainage of rainwater and prevents the pores in the surface from clogging when the joints are swept in.

Drainage joint blocks are joint-tight paving blocks in accordance with DIN EN 1338. They drain rainwater into the superstructure via the joint space. This requires a balanced ratio of stone surface to joint surface. For this reason, the edge length is limited to a maximum of 40 cm and the joints are wider than prescribed by regulations for conventional paving. There are no fixed rules that define this ratio; it is ultimately based on experience and measurements. To ensure barrier-free use, the average joint width of 15 mm should not be exceeded, but special specifications can also limit joint widths that deviate from this. The dense concrete structure of drainage joint pavers has advantages:

Hard stone chippings with a grain size of 2-5 mm have proven themselves as a bedding material, the joints are usually filled with 1-3 mm chippings. This ensures rapid drainage of rainwater through the paving. However, the coarse aggregates also cause dirt and dust to be washed into the pavement surface and accumulate on the surface of the base course at the latest. In the long term, this reduces the infiltration capacity, which is why the information sheet for infiltration-capable traffic areas (M VV) recommends a runoff coefficient of between 0.3 and 0.5. Above an average traffic load of 300 vehicles per day, rainwater runoff must not be discharged untreated into a body of water or infiltrated.

By using a special joint material, dirt, dust and pollutants are filtered out of the rainwater. This construction method has been tested by the DIBt and is regulated by a general construction type approval (aBG). This gives the surface covering the additional function of a treatment plant for rainwater(proWater). Fine particles and pollutants are retained close to the surface in the joints and cannot permanently impair water permeability. The paving surface must be cleaned regularly every 10 to 15 years using the rinse-and-soak method. The joints are emptied to a depth of 2 - 3 cm and then refilled up to the top edge. The water permeability is reduced to a value that corresponds to approx. 90 % of the infiltration capacity when new. It is therefore permissible to apply an average runoff coefficient of 0.0.

As little moisture is stored in the joint space between the drainage joint stones, a positive influence on the microclimate through evaporation is hardly noticeable.

GDM.KLIMASTEIN is a combination of aggregate-porous and structure-dense stone and the world's first three-layer paving stone with a structure-dense facing, an aggregate-porous storage layer and a capillary layer as a base. Thanks to the three-layer structure, it has been possible to combine all the positive properties of the aforementioned systems in one product.

When it rains, the rainwater seeps away through the joints. Once it has passed through the facing layer, it is absorbed and retained by the underlying storage layer so that it can evaporate into the surrounding air after the rain. Measurements have shown that with a stone thickness of 8 cm, 10 liters of rainwater can be stored per square meter. The basis of the GDM.KLIMASTEIN is the so-called capillary layer.

Filled capillary pores prevent moisture from the storage layer from being released directly into the bedding, but at the same time ensure that residual moisture is transported from the bedding into the storage layer against the force of gravity. As a result, the evaporation capacity of GDM.KLIMASTEIN can be increased to over 50% of the annual amount of precipitation. This corresponds to the amount of moisture that a meadow can evaporate. Infiltration, evaporation and filtration are the most important building blocks for redesigning settlement areas according to the sponge city principle and thus preparing them for the challenges of climate change.

Paving systems with porous aggregates are recommended for pavements up to load class Bk0.3. This load class is assigned to residential paths and residential streets, for example. Although GDM.KLIMASTEIN is manufactured with porous layers, it fully meets all the requirements for concrete paving blocks with a dense structure in accordance with DIN EN 1338, making it suitable for infiltration-capable traffic areas up to load class Bk1.8, i.e. a traffic load 6 times higher than conventional porous paving systems.

The potential for traffic areas on which the proactive properties of GDM.KLIMASTEIN can unfold is correspondingly greater. Roads up to the "main village street" category and even roads in smaller commercial areas can be separated from the sewer network. Furthermore, as more and more cities and municipalities are tending to reduce the speed limit in urban areas to 30 km/h, the conditions for the use of paving stones with proactive properties in traffic areas are improving. As the traffic load increases, so does the pollutant load of rainwater. However, when grouted with the special joint material in accordance with the general construction type approval (aBG), heavy metals, hydrocarbons and microplastics are already filtered out as they flow through the joints. In order to protect the groundwater from contamination, no additional systems for precipitation water treatment away from the carriageways are therefore required.

We live in the age of cities. Drought and heat stress affect the urban climate. Heavy rainfall events are on the increase. Time for a solution to rethink paving. Time for paving stones that achieve a significantly higher evaporation rate, are almost as high as a meadow and can do even more for the city of the future.

A PAVING STONE HAS THREE TASKS IN THE CLIMATE-RESILIENT CITY OF THE FUTURE

The GODELMANN proActive properties for a better urban climate at a glance:

proDrain

Decentralized surface infiltration helps to keep the natural water balance on site as intact as possible and relieves the burden on the sewer network.

proVapo

Evaporation activity improves the urban climate: higher humidity and more cooling.

proWater

The joint material filters pollutants out of rainwater from traffic areas: Groundwater protection.

proAir

Thanks to a modified concrete formulation, the surface contributes to the reduction of air pollutants

proReflect

The surface reflects the heat of solar radiation and protects against overheating.

proSilence

Certain formats, the joint width and surface structure, as well as the laying pattern guarantee a particularly quiet paving surface.

proCycle

Conserves raw material resources through recycling and upcycling.

proPower

Intelligently arranged spacers on the stone flanks create a positive and force-locking bond.

Since 2021, our family-owned company has been awarded the prestigious Cradle to Cradle Certified® Gold - the first concrete block company in the world to do so.

Cradle to Cradle certification assesses the recyclability of products and rethinks production processes. Cradle to Cradle literally means 'from the cradle to the cradle'. Valuable raw materials should not be wasted, but reused indefinitely. The premise is that products should be 100% recyclable after use and can be reused as raw materials in a completely environmentally friendly way.

For ecological reasons, de-icing agents should not be used for green and permeable surfacing of traffic areas. De-icing salts have a corrosive effect on concrete and, above all, damage the environment and, over the years, the appearance of the pavement. It is recommended to grit with 1/3 mm or 2/5 mm grit instead. In the case of green paving, excess material must be removed at the end of winter.

When clearing snow, always ensure that the paving is not damaged. We recommend clearing the snow with a broom or snow blower. Snow blades may only be used with a Vulkolan/plastic blade. In order to prevent damage to vegetation, snow blowers are preferably used for snow removal on green surfaces.